Stainless steel chain products are used very widely.

Are these chains really safe?

What’s the TIG welding?

[Table-1] Tensile test results SUS304 wire diameter 5mm chain

Table 1 shows that chain with a remarkably low breaking load is being sold.

Their external appearances are similar, so why are the test results so different?

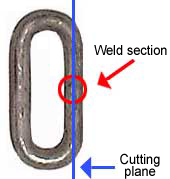

See the sectional photographs of the weld sections.

|

Photograph 1

|

Photograph 2

|

| After the weld section is cut and the cutting plane is washed with acid, the color of the welded part changes. |

Sectional photograph of weld section of chain made by our company |

Sectional photograph of weld section of imported chain made by C |

* The discolored part in the center is the weld section.

Photographs 1 and 2 are sectional photographs of weld sections.

Comparing photographs 1 and 2 shows that the fusion depth of the weld section is shallower.

The fusion depth is shallower, which means that the chain link is not fully connected.

Tensile test sample

Photograph 3

|

Photograph 4

|

| Chain made by our company after tensile test (Break location is on the end at the left.) |

Imported chain made by C after tensile test (Break location is on the end at the left.) |

Photo 4 shows that the chain broke before being stretched.

A chain is made by connecting individual links. Each link must be securely welded.

If the welding of even one link of a chain is defective, it can cause a truly disastrous accident.